Top Tips for Choosing High-Quality Building Materials

When starting a construction project, the strength of your structure depends on the quality of materials used, from the ground pavers to the roof trusses. In a world where sales pitches can hide the true durability of materials, savvy buyers need to be careful, especially in areas prone to hail or harsh weather. Sustainability is now a crucial factor affecting the longevity and eco-friendliness of a build, not just a trendy term. Keep reading to discover how to carefully examine the materials chosen by your builder, ensuring that your project can withstand the test of time and nature.

Key Takeaways

Quality Materials Lead to Durability and Reduce Long-Term Costs

Material Selection Impacts Sustainability and Energy Efficiency

Professional Inspections Ensure Adherence to Quality Standards

Timing of Inspections Is Crucial for Identifying Issues Early

Learning From Past Projects Helps in Making Informed Material Choices

Understanding the Importance of High-Quality Materials in Construction

When embarking on a building project, the significance of selecting high-quality materials like polyvinyl chloride or premium lumber can't be overstated. A focus on quality not only curbs issues like water damage and inefficient heat transfer but also ensures that any renovation will stand the test of time. Builders and homeowners alike benefit from the durability and longevity that come with making the right choices in materials. This not only prevents costly repairs but also enhances the overall value of the property, making it a wise investment for the future.

Why Quality Matters in Building Projects

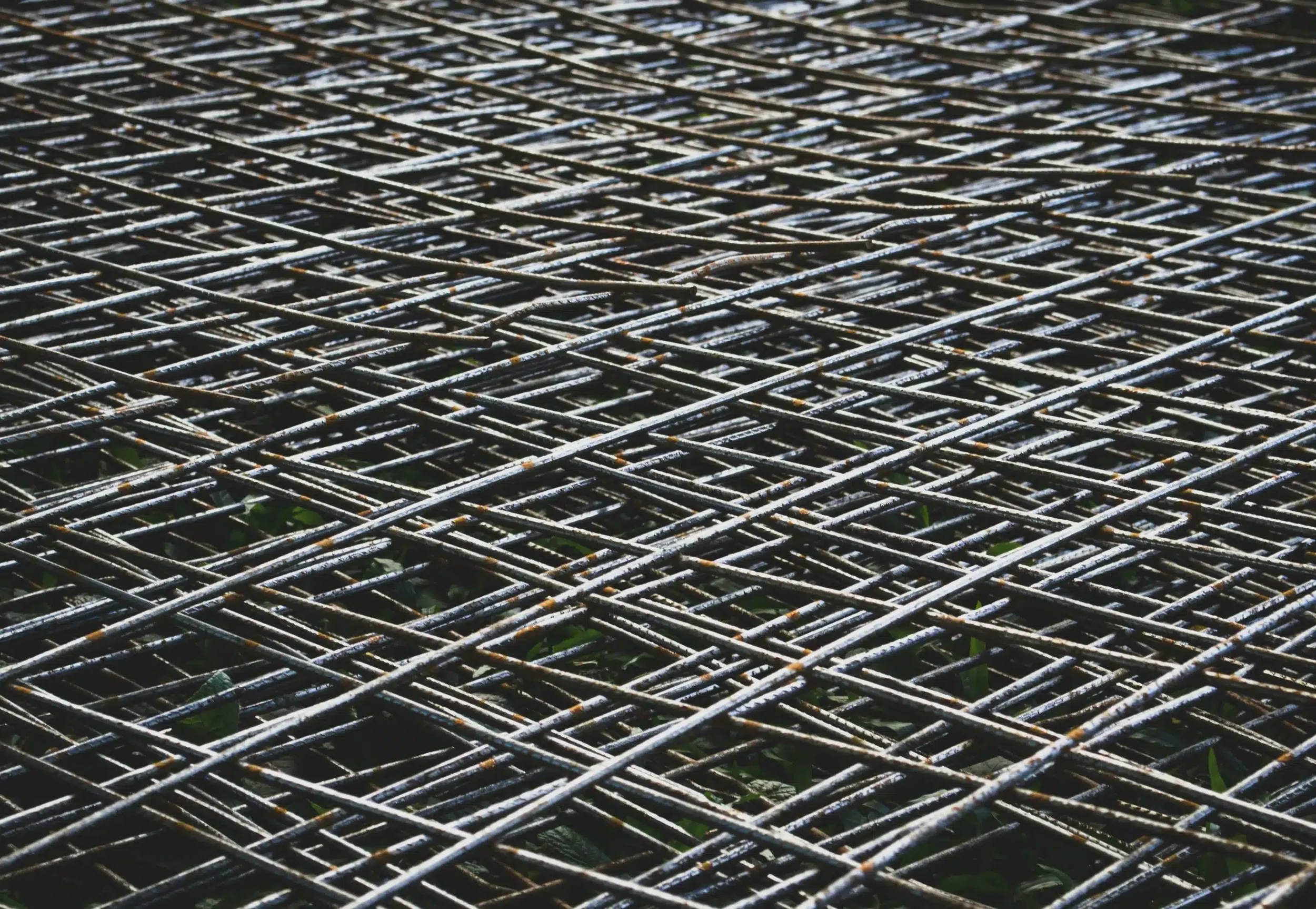

In the field of construction, the choice of materials is crucial for the integrity of buildings, whether they are skyscrapers or simple homes. Engineers place great importance on selecting high-quality materials. Softwoods are valued for their versatility, while cork is chosen for its sustainability.Carbon-infused building solutions are preferred for their strength. These choices have a direct impact on the durability, safety, and energy efficiency of a project, and they form the foundation of any long-lasting structure.

| Material Type | Sustainability Factor | Common Usage |

|---|---|---|

| Softwood | Renewable | Residential framing, interior fixtures |

| Cork | Eco-friendly, biodegradable | Insulation, flooring |

| Carbon-infused Solutions | Longevity, reduces carbon footprint | Reinforcement in concrete structures |

The Long-Term Benefits of Choosing the Right Materials

Investing in top-quality materials like renewable resources, sturdy brick, and advanced plumbing systems pays off in the long run by drastically reducing maintenance costs. Innovation in technology provides materials that last longer, stand up better to the elements, and ultimately lead to a more sustainable, cost-effective build. The foresight to choose materials wisely manifests in a home that remains solid and reliable for decades, safeguarding the homeowner's investment and peace of mind.

Reduction in long-term maintenance costs due to durability

Usage of renewable resources supports environmentally friendly practices

Integration of modern technology ensures up-to-date construction standards

Investment in quality plumbing avoids future leaks and water damage

Building with brick enhances fire resistance and thermal efficiency

Strategies to Ensure Your Builder Chooses Quality Materials

Navigating the complexities of construction requires a proactive approach to maintaining high standards. By setting clear quality benchmarks early on, homeowners can ensure that materials like robust wood, resilient precast concrete, and efficient metalroofs are incorporated appropriately. At the heart of a sturdy building lies a well-constructed building envelope, which can be safeguarded by implementing quality checks throughout construction. Streamlining material selection by providing builders with a preferred list also curbs the risk of subpar substitutions. This tactic is particularly useful for materials that may be reclaimed through deconstruction, promoting an eco-friendly build. Emphasizing these strategies builds a foundation for excellence and integrity in any construction undertaking.

Setting Clear Quality Standards From the Start

Establishing clear quality standards from the onset of any construction project is paramount. Ensuring your builder understands the level of quality expected for the foundation, the durability of the glass installations, the design's intricacy, the roof's robustness, and the grade of copper used in wiring and pipes form the bedrock of the project. This initial step emboldens homeowners to demand the highest standards that align with their vision, safe in the knowledge that no corners will be cut in creating their ideal structure.

Incorporating Quality Checks at Each Project Phase

Quality control at every stage of construction helps reduce waste, make the best use of natural resources, and support the project's sustainability policy. Builders ensure a high-quality product by doing systematic quality checks from the foundation to the framing, all the way to the final finishes. Materials like bamboo, known for its strength and ability to grow quickly, show where responsible resource use and quality construction practices come together.

| Construction Phase | Quality Check Action | Benefit |

|---|---|---|

| Foundation | Soil testing, concrete strength assessment | Ensures structural integrity and longevity |

| Framing | Inspection of lumber, including bamboo | Verifies durability and supports eco-friendly building |

| Finishes | Review of installation techniques, materials quality | Enhances aesthetic appeal and functional life |

Creating a Preferred Materials List for Your Builder

Creating a preferred materials list is a smart move to ensure your builder uses materials that withstand the tests of time and nature. This catalog should detail your expectations regarding crucial elements like transport durability, wallconstruction standards, waterproofing capabilities, snow load resistance, and the grade of steel required for structural integrity. By doing so, you give clear instructions, reducing the likelihood of inappropriate material substitution that could compromise your building's quality.

Specify the level of steel quality to uphold structural stability, especially in load-bearing designs.

Detail the waterproofing standards for areas vulnerable to moisture to prevent water damage.

Ensure materials chosen for walls have been vetted for their durability during transport to the site.

Include specifications for materials that can withstand heavy snowfall, preventing future roof complications.

Communicating With Your Builder About Material Choices

Engaging in direct and transparent communication with your builder sets the stage for success in your construction project. It's imperative to articulate your expectations regarding the reuse of materials, which not only contributes to environmental responsibility but also the long-term resilience of the building against potential flood damage. Asserting the value of high-caliber raw material is crucial for preventing issues like mold and ensuring the lasting beauty of the final structure. Discovering ways to converse about the importance of material quality without escalating costs is essential for maintaining a healthy relationship with your contractor and achieving the desired outcome for your build.

Effective Communication Techniques With Contractors

To streamline your discussions, present clear information to your builder regarding the expected quality and application of key materials, such as polystyrene for insulation or mud for stucco finishes. Emphasize the economic benefits of using durable roofing materials that provide long-term savings. This approach facilitates mutual understanding and promotes alignment of your project's goals with your contractor's execution plan.

How to Discuss Material Quality Without Increasing Costs

Discussing the importance of using high-quality materials such as non-porous fiberglass that resist fungus growth doesn't have to raise the project's overall costs. Homeowners can emphasize the long-term cost savings of using durable materials in areas like the garage, which can help minimize future expenses. Addressing these specifications early in contract discussions can align both parties' expectations and avoid surprise costs.

Identifying High-Quality Building Materials

Choosing the right building materials is vital for the durability and longevity of a construction project. These materials should be strong, environmentally friendly, and energy-efficient to save on maintenance costs and reduce environmental impact. However, identifying such materials requires knowledge of manufacturing processes and an understanding of certifications that ensure quality. Homeowners and builders must make well-informed decisions about the materials they use to shape their construction projects.

Key Characteristics of Top-Quality Materials

In pursuing enduring structures, identifying high-quality building materials is akin to setting the stage for exceptional carpentry and structural resilience. Top-quality materials display an innate durability that can withstand the harshest elements, from the relentless pummeling of a storm to the slow sculpting forces exerted by time. Notably, composite material offers the versatility needed for modern applications while clay and reinforced concrete provide proven longevity in traditional and contemporary building designs alike.

| Material | Characteristics | Usage in Construction |

|---|---|---|

| Composite Material | Versatile, lightweight, resistant to rot and decay | Decking, roofs, exterior cladding |

| Clay | Natural, durable, offers excellent thermal mass | Brick construction, tiles |

| Reinforced Concrete | Strength, able to bear heavy loads, resistant to fire and weathering | Foundations, structural frames, storm shelters |

Resources to Help You Identify High-Quality Materials

Securing the right information to distinguish high-quality materials can be as straightforward as consulting with scientific experts or accessing detailed reports on the water resistance of certain plastics. Additionally, studies on how materials react to carbon dioxide exposure or the longevity of specific metals in varying environments offer valuable insights for builders and homeowners keen on using materials backed by science.

The Role of Inspections in Verifying Material Quality

The vigilance in upholding material standards during construction is essential, and professional inspections are a critical tool in this process. Deploying experienced inspectors at strategic stages ensures that the rain won't seep through substandard thermal insulation, that the oak used for the stairs meets industry quality criteria, and that the concrete poured for the foundation sets with the required density and strength. Scheduling these inspections during specific phases of the build, like post-framing or pre-finishing, allows for timely identification and resolution of potential issues, helping to maintain the integrity of the project from the ground up.

How Professional Inspections Can Ensure Material Standards

Professional inspections are critical tools in safeguarding material standards. They ensure that components like hardwood in flooring applications are free of defects and that the paper layer under shingles is correctly installed to prevent leaks. Inspectors are also equipped with the tools necessary to test the integrity of rock foundations, serving as an indispensable safeguard in the building process.

When to Schedule Inspections for Best Results

Timing inspections is key to ensuring quality. Ideally, they should be arranged after major milestones, such as setting columns or pouring foundations with innovative materials like hempcrete, when soil conditions can significantly impact stability. By coordinating inspections following the application of critical elements like mortar, you can demand higher standards and rectify any issues promptly, thus supporting the structure's enduring resilience.

Learning From Past Building Projects

Learning from past building projects provides valuable insights into choosing quality materials. Builders and clients understand material performance better by studying examples where engineered wood exceeded expectations or the right kind of tree enhanced sustainability. Avoiding common mistakes, like using poor-quality sand or neglecting moisture effects on air conditioning, helps prevent repeating past errors. These lessons guide informed, strategic decisions, ensuring safe, durable, and cost-effective construction.

Analyzing Case Studies of Successful Material Selection

Industry case studies show that choosing the right materials is crucial for building integrity. Projects using high-grade steel beams from reliable suppliers often have better stability and longevity. Terracotta’s thermal resistance and aesthetic appeal highlight its value in insulation, while using quality oak for furniture enhances the user experience.

Common Pitfalls to Avoid in Material Selection

Avoiding the common mistakes in material selection is crucial for any construction project. For instance, choosing a subpar basementwaterproofing product can lead to costly damage, while the wrong type of window could fail to meet energy efficiency goals. Additionally, opting for an inferior stucco exterior without considering innovative materials like mycelium can miss out on the benefits of green building practices, resulting in a finished structure that falls short of today's sustainability and performance standards.

Conclusion

Ensuring your builder opts for high-quality building materials is crucial for the longevity and safety of your property. High-quality materials reduce maintenance costs and contribute to a greener, more sustainable build. Clear communication and setting firm standards with your builder help prevent the risk of substandard substitutions. By prioritizing quality material selection, homeowners safeguard their investment and achieve a durable and aesthetically pleasing home.